Homemade sharpening center for lathe chisel and other things that are dull. Good grinding wheels are a must for HS steel. Plans can be found here: http://shapewood.co.uk/Documents/sharpe1.PDF

Wednesday, July 01, 2009

Homemade sharpening center for lathe chisel and other things that are dull. Good grinding wheels are a must for HS steel. Plans can be found here: http://shapewood.co.uk/Documents/sharpe1.PDF

Thursday, February 22, 2007

Friday, August 25, 2006

Monday, August 07, 2006

Sunday, August 06, 2006

Saturday, August 05, 2006

Thursday, August 03, 2006

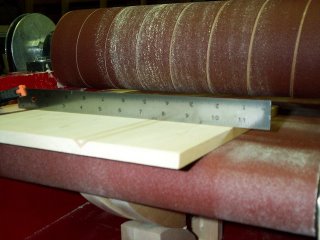

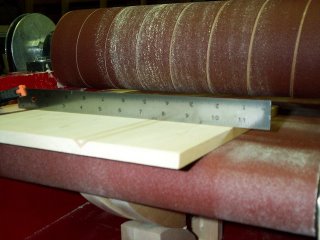

It's hard to convey just how flat a board is with a picture. This one is pretty flat. It's within .005" on each side near the edge. You cannot feel the seams of the glue-up with your fingers, you have to look real hard to see them. I'm happy. Time to build a dust hood now that I know it's going to work correctly.

I did get a spare motor just for the drum sander. But it was all ready to go sitting on top of the saw so I tried it. It worked better than I thought. Belt tension is pretty easy, just lower the arbor. The BT3100 that this is sitting on works with a speed controller. I was able to slow the motor down in order to sand the drum. The glue was getting to hot on the drum and gumming up the sandpaper. Slowing down the rev's help a bunch.